NDIR Gas Sensors and Analyzers

Most NDIR gas sensors use broadband light sources, gas chambers with highly reflective walls, optical filters, detectors, and electronics for signal processing.

Most NDIR gas sensors use broadband light sources, gas chambers with highly reflective walls, optical filters, detectors, and electronics for signal processing.

Most NDIR gas sensors use broadband light sources, gas chambers with highly reflective walls, optical filters, detectors, and electronics for signal processing. Infrared absorption occurs at the infrared energy (i.e. wavelength) specific to the target gas, which means that it is highly selective for a particular gas, which is key for NDIR gas detection.

Nondispersive infrared (NDIR) spectroscopy is often used to detect carbon dioxide, nitrogen dioxide, sulfur dioxide and other gases, and measure their concentration levels. At high concentrations, these gases can be lethal or explosive, making monitoring of these gases imperative in some environments.

The technique is called non-dispersive because no dispersive elements are used (e.g. prisms or diffraction gratings) and the wavelength passing through the sampling chamber is not pre-filtered.

When infrared radiation interacts with gas molecules, infrared light is absorbed by the gas molecules at a specific band or wavelength, causing vibration of the gas molecules and absorption. The ratio of transmitted radiation energy to the incident energy reaching the detector, is dependent on target gas concentration. NDIR gas sensors detect the decrease in transmitted infrared light which is in proportion to the gas concentration.

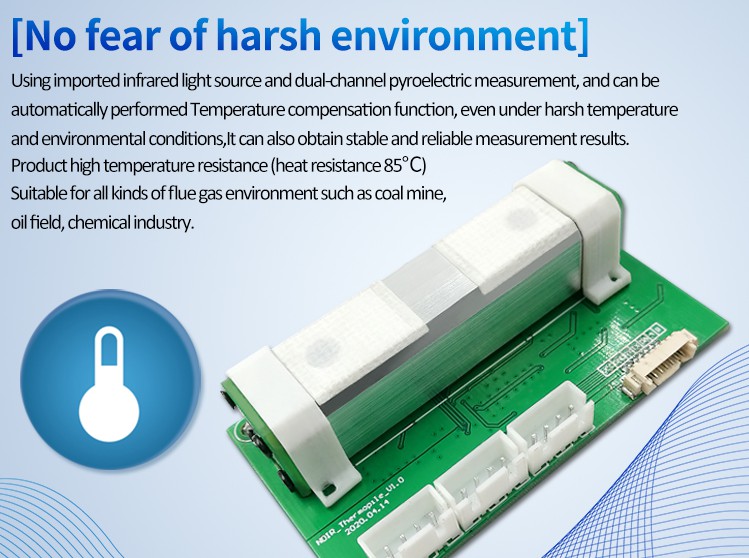

The level of infrared light that the detector receives plays an important role in sensor drift and measurement accuracy. The infrared light source will have degradation of illumination over time from film buildup and age. There are also environmental factors to consider. The effects of temperature on NDIR gas sensors are complex and care must be taken as changes in temperature reflect the absorbance, SPAN and apparent gas concentration.

Single channel NDIR gas sensors often use electronics with complex algorithms for temperature compensation. The thermopile (IR) detector senses temperature by absorbing radiation, but it also responds to changes in ambient temperature which can give rise to spurious and inaccurate signals. For this reason, many NDIR sensors use a thermistor integrated into the package or use a dual wavelength sensing configuration to create a reference and incident light level comparison.

In the single sensor NDIR application thermistors are often used over temperature sensors. Pulsed and filtered IR light is applied to the series connected active junctions. The junctions are heated, which in turn generates a small thermoelectric voltage. The temperature of the reference junction is measured with a thermistor. The potential at the junction between the resistors can then be used to determine the thermistor resistance and the temperature. Use of a the thermistor in the sensor is more accurate than testing ambient temperature because the NDIR gas sensor will be slightly heated (often as much as 2 – 5 degrees) by the IR light source.

Dual wavelength type gas sensors use one light source, but have two detectors and two optical filters of different wavelengths which are placed in front of each detector. The reference wavelength selected is one that is unaffected by the sensed gas. As the infrared light source changes over time, the gas measurement can be compensated accordingly, eliminating sensor drift errors. In this way changes to lamp output (due to aging, temperature or other ambient conditions) can be accounted for and eliminated from the results.